IoT’s role in positive environmental impact and sustainable business.

The narrative changed around ecommerce sustainability. No longer a niche ‘nice-to-have,” sustainability transitioned from an operational feature to an operational requirement. Increased pressure from stakeholders and consumers leaves retailers working into overdrive as they begin to implement more sustainable business models.

Additionally, amended sustainability and decarbonization goals for 2025 and beyond means there’s an added urgency around collective collaboration layering the already urgent need to transition from linear to circular. Yet the question remains, are we taking the necessary steps to make these goals a reality?

The Problem

Despite efforts and demands, progress towards environmental sustainability in logistics, as one piece to the puzzle, remains halted, or rather, it remains reactive, for three reasons. First, we’re reacting to a problem not only larger than any one retailer or consumer but larger than just the environmental impacts. Second, we’re reacting to said problem at an individual scale, rather than scaling the solution to be more collaborative and overall circular. Third, we’re reacting to a problem we can’t really even see because the lack of visibility across supply chains leaves us holding onto what we know rather than what is possible.

For example, packaging, despite sustainability demands, remains designed for recycling rather than for reuse. But waste management systems are severely underfunded; not to mention, we’re producing more waste than we know what to do with. Therefore, recycling methods are currently inefficient and insufficient in their processes. While EPR legislation is working to hold retailers accountable for the wasteful packaging they produce, encouraging redesign, most new legislation is focused on taxing the use of virgin plastics, further emphasizing recyclability as the ultimate goal, opposed to extending life cycles through reuse.

So, how do we get from a place of reactivity to a place of response? Of course, the system will not change overnight. But there are steps we can take, call them ‘low-hanging fruit,’ which when implemented collectively, become largely impactful.

The Opportunities in IoT and Reusable Packaging

As anyone who struggled to track down toilet paper in Spring of last year could tell you, while exacerbated by the pandemic, there are gaps in the current supply chain system. The supply chain, as it is now, requires an added sophistication to evolve it because data remains centralized. Centralized data makes it difficult to share proprietary information across the supply chain and difficult to manage inventory when shipments are halted as retailers are forced into bidding wars for shipping containers and freight space.

What’s more, centralized data isn’t timely, meaning decisions made from its analysis are delayed and homogeneous – not fit for the multifaceted problem we’re facing and not sufficient enough to respond with because there’s little value in disconnection. In other words, the horizontals aren’t connected with the verticals, and that disconnect, those gaps, are where the challenges continue to drain value and opportunity.

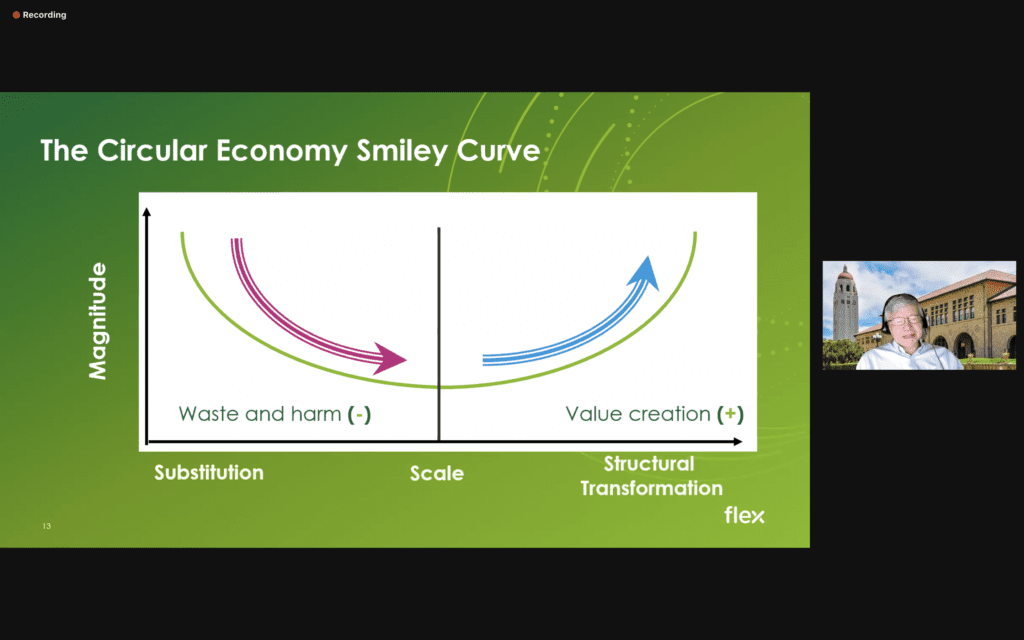

The Smiley Curve

Dr. Hau Lee, professor at Stanford University, offered the Smiley Curve in his webinar presentation for SupplyChainBrain in explaining how we achieve a circular economy.

By implementing reusable packaging, as a vehicle for IoT data collection, retailers can pick the lower hanging fruit to essentially progress past what Dr. Lee calls substitution. Substitution refers to improving the current system – in this case, the supply chain – by way of substituting what we’ve been doing with new innovative methods, such as reusable packaging with IoT. Further, the Smiley Curve, as shown above, illustrates how scalability, in response to our multifaceted problem, propels the economy from waste and harm to value creation and repair.

Therefore, at LimeLoop, we believe that scalability, visibility, collectivity, and accountability are the four dots worth connecting to carry us from reaction to response and from substitution to structural transformation. Decentralizing data – data collected by way of reusable packaging with IoT – is, then, how we connect those dots, to then, decarbonize the planet.

The Dots Worth Connecting

Scalability

Change happens as if it is a ripple across the surface of water. One drop, and the entire surface integrity is altered. Perhaps only for a moment, but that ripple shifts the state of things nonetheless. So how do we take a small- to medium-sized apparel retailer, for example, who’s established a successful reusable packaging program, and ripple their success across industries – food, pharmaceuticals, raw materials, etc. – to then scale-out at a higher level, so that real-time data collected in California is shared with those across the supply chain, including overseas?

A LimeLoop package, by design, may be reused up to 200 times. This long lifespan makes it the perfect vehicle for IoT integration. Each package becomes its own data-hub, collecting real-time data on the environment in and around the package throughout its journey. But, what makes this platform a remarkable host for scalability, is the opportunity for reverse logistics and predictive analytics to inform the outcomes of future business decisions.

When retailers are equipped with a closed feedback loop informed by data shared across the supply chain, business decisions regarding environmental impact become measurable and actionable – taking retailers from a place of response to a place of proactivity. This quantification adds value to the upward climb that is decentralizing data, which, then, moves retailers from substitution to scalability – the next step in transitioning from linear to circular.

Visibility

Data is incredibly siloed, as it’s currently collected and stored. An order is placed. A package is shipped. That package then receives a tracking number, which only informs of its last location. The package arrives a day late – delays in delivery, then, impact the consumer – which doesn’t, then, inform the retailer anything about the package. Why was it delayed? Was it opened? When was it opened? If it was a temperature sensitive or temperature controlled package is it still safe with that delivery delay? A retailer is left with so many questions, there’s little data to go on to ensure delays don’t continue or that the package’s integrity wasn’t compromised.

Tracking and the Post-Purchase Experience

Additionally, consumers demand better ecommerce experiences – customization, personalization, first-day delivery, transparency, sustainability – but the possibilities in achieving these new experiences, especially around the holidays, are limited within the current system. When consumers track their packages, now, they get a vague impression of their package’s status – ‘out for delivery’ – and they get an estimated delivery date and time range. Upwards of 50-70% of customer service inquiries are asking ‘Where is my order?’ When the package does arrive – hopefully without delay – retailers don’t have the means of following up with consumers. And not to mention, the single-use packaging retailers paid for and put effort into personalizing will be landfilled.

In other words, the lack of visibility into the post-purchase experience, but also into the supply chain, holistically, begs the question, “who has what and where?” With supply chain shortages continuing into 2022, retailers scramble to make up for the losses in manufacturing components, supplies, and shipping.

Decentralized data reveals those hidden opportunities in post-purchase experiences and in supply chain hierarchies by providing retailers the means to follow-up with consumers in real-time with social media messaging or personalized feedback inquiries. Also, this data allows 3PLs and carriers to communicate with retailers about inventory, storage, and shipping. This data, as a reminder, wouldn’t exist without reusable packaging and IoT.

Collectivity

Because a LimeLoop reusable package collects real-time data at every touch point along the supply chain, retailers implementing decentralized data spread decision making by including everyone from the consumer to a retailer’s 3PL and carriers, in the growth and operations of a retailer – taking specialization to a new level.

Furthermore, because of its scalability, reusable packaging with IoT not only connects all personas involved in getting a package from order to delivery, but it connects industries and countries. Collaboration is key in shifting from substitution to scalability and, then, to structural transformation. Decentralizing data on environmental impacts, connects retailers by allowing them to work together rather than compete for solutions.

Healthy business requires some competition, but when it comes to repairing the damage done to the planet and our supply chain, collectivity must be at the forefront. And it certainly isn’t easy to gather each player – all with their own perspectives, opinions, and agendas – in one place to hash out actionable steps towards a circular, sustainable future. But with reusable packaging and IoT, we’ll already be connected once we decentralize data. Only with common goals which are measurable and quantifiable, may progress once again catch steam after coming to, what feels like, a screeching halt.

Accountability

Decentralizing data democratizes an industry. The lack of visibility is not only a problem throughout the supply chain, but it’s also a problem for retailers marketing sustainable practices and following through versus retailers utilizing sustainability as a front. This isn’t to point fingers, or to play the blame game, but there’s almost a shroud of secrecy surrounding data because it is a valuable tool in doing business.

But progression requires accountability across industries and supply chains. Retailers must be held accountable for their practices, including their packaging and shipping. Reusable packaging and IoT hold them accountable because the numbers don’t lie. Quantifying environmental impacts illuminates their true environmental impact. It not only illuminates it, but it stores it, creating a historical log of a retailer’s sustainability.

Ready for Reuse?

Get started with one of our Reuse Specialists today and start doing good with data.